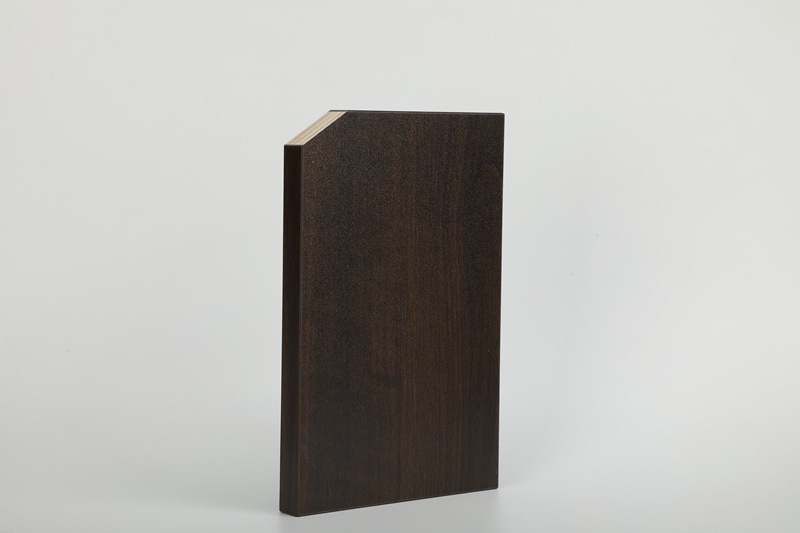

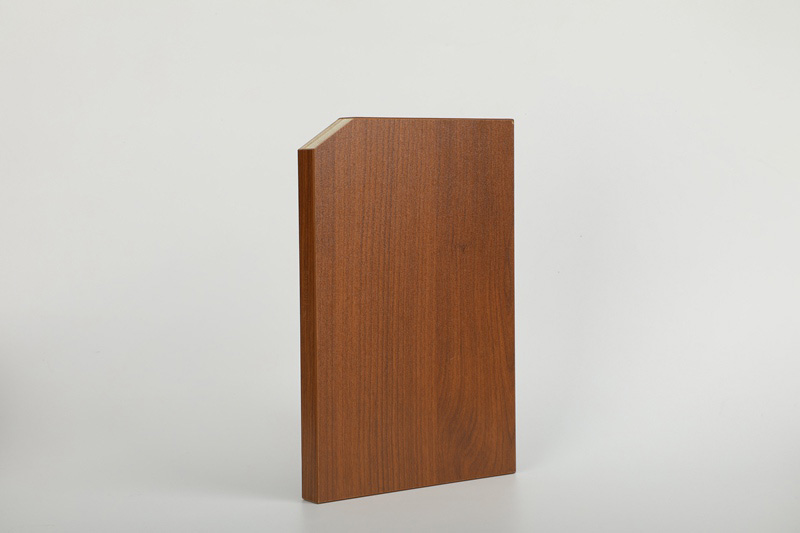

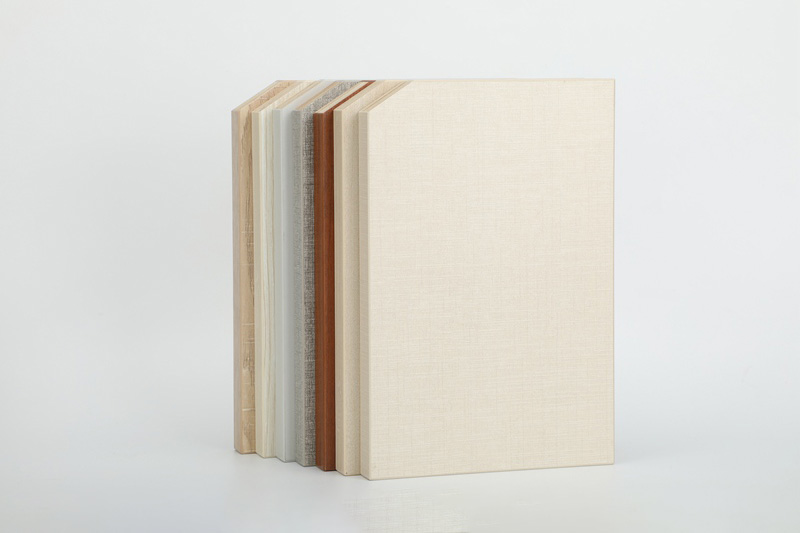

Multi Ply Plywood

Please click the button below to contact us.

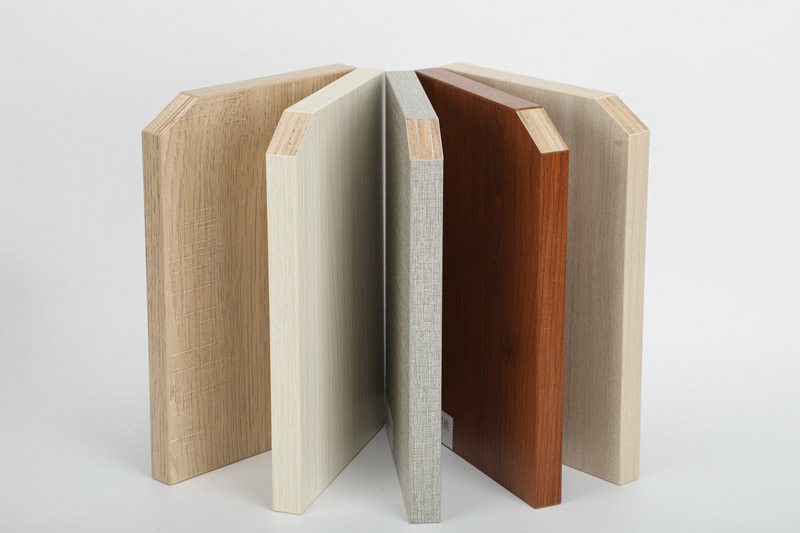

Introduction:Multi Ply Plywood is a board made of multiple layers of veneer glued vertically and cross-bonded with adhesive. Its unique laminated structure gives it high strength, deformation resistance and weather resistance, and is widely used in construction, furniture, packaging and transportation.

Product Description

Multi Ply Plywood is a board made of multiple layers of veneer glued vertically and cross-bonded with adhesive. Its unique laminated structure gives it high strength, deformation resistance and weather resistance, and is widely used in construction, furniture, packaging and transportation. Compared with solid wood boards, multi-layer plywood has lower cost and stronger stability, and is an indispensable basic material in modern industry.

Multi Ply Plywood Parameters:

| Item | Parameter |

| Place of Origin | China |

| MOQ | 1000 pc |

| General Specifications | 8mm, 18mm |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Regenerated Wooden Base |

| Transportation | By Sea/By land |

| Quality/Safety Certification | GB/T19001-2016/ISO9001:2015, Hi-tech Enterprise, Attestation of Chinese Environment Mark |

Features of Multi Ply Plywood

1. Multi-layer vertical cross structure

The number of veneer layers is usually an odd number (such as 3 layers, 5 layers, 7 layers, etc.), and the texture direction of adjacent layers of veneer is vertically crossed, which effectively offsets the internal stress of the wood and reduces the risk of warping and cracking.

2. High strength and impact resistance

The transverse static bending strength is ≥40MPa, and the longitudinal static bending strength is ≥50MPa, which is far higher than ordinary solid wood boards and is suitable for load-bearing structures. The transverse elastic modulus is ≥4000MPa, and the longitudinal elastic modulus is ≥6000MPa. It has strong deformation resistance and is suitable for dynamic load scenarios.

3. Environmentally friendly adhesives and low formaldehyde release

Use E1 or ENF grade environmentally friendly adhesives (such as phenolic resin, urea-formaldehyde resin modified adhesive), formaldehyde release ≤0.03mg/m³ (ENF grade), in line with international environmental standards (such as CARB P2, FSC certification).

4. Dimensional stability and weather resistance

Moisture content control: During the production process, the moisture content is strictly controlled between 8%-12%, adapting to different climate environments and reducing expansion or contraction caused by humidity changes. Weather resistance test: After 72 hours of hot and cold cycle test (-20℃ to 60℃), the board size change rate is ≤0.3%, suitable for outdoor or large temperature difference environment.

Application scenarios of Multi Ply Plywood

1. Construction and engineering

Formwork and scaffolding: 18mm thick board is used for concrete pouring formwork, which can be reused more than 10 times, with compressive strength ≥25MPa, reducing construction costs.

Wall and floor base: 8mm thick boards are used for lightweight partitions or floor bases, and the sound insulation performance is improved by 30%. It is better when used with sound-absorbing cotton.

2. Furniture manufacturing

Cabinet and table tops: 18mm thick boards are used for wardrobes, bookcases and other cabinets, with a load-bearing capacity of 80kg/m², and the surface can be directly covered with veneer or melamine paper.

Curved furniture: Through the hot pressing process, special-shaped furniture such as curved chair backs and wavy table legs can be made, and the minimum bending radius is 15 times the thickness of the board.

3. Packaging and transportation

Heavy-duty packaging boxes: 18mm thick boards are used for machinery and equipment packaging, with an impact resistance of 50%, passing the ISTA 3A transportation test to protect the safety of goods.

Pallets and pallets: 8mm thick boards are used for logistics pallets, with a static load capacity of 2 tons and a dynamic load capacity of 1 ton, and a service life of 3 times that of ordinary wood.

4. Vehicle and shipbuilding

Carriage lining: 18mm thick boards are used for truck and container linings, with a 40% increase in wear resistance. The surface can be coated with anti-corrosion paint to extend the service life.

Yacht deck: With anti-slip veneer, it is used for yacht decks or cabin partitions. The anti-slip coefficient is ≥0.6 (wet state), which meets ISO 14122-3 standards.

5. Art and decoration

3D stereo wall panels: Through CNC engraving technology, three-dimensional patterns are made on 8mm thick boards, and LED light strips are matched to create dynamic light and shadow effects.

Exhibition props: Used for exhibition background boards and display cabinets. They are lightweight and high-strength, easy to transport and assemble, and the weight of a single board is only 1/3 of that of solid wood.

Cleaning and maintenance of Multi Ply Plywood

1. Daily cleaning

Dust cleaning: Use a soft brush or vacuum cleaner to remove surface dust and avoid scratches from hard objects.

Stain treatment: Use neutral detergent (pH 6-8) to wipe stains such as oil and ink. Use alcohol (concentration ≤70%) to wipe stubborn stains. Avoid soaking for a long time.

2. Moisture and mildew prevention

Humidity control: Keep the humidity of the storage environment between 40%-60%, avoid direct contact with water or long-term exposure to humid environment.

Mildew prevention: It is recommended to apply waterproof paint or mildew inhibitor for outdoor use, and check the edges regularly for warping or mildew.

3. Repair and maintenance

Surface scratches: Mild scratches can be filled with wood wax oil of the same color, and deep scratches need to be replaced or veneered.

Structural damage: If the glue layer is cracked, it needs to be re-applied with glue and pressed to fix. It is recommended to use the same adhesive as the original board.

FAQs of Multi Ply Plywood

Q: What is the minimum order quantity (MOQ)?

A: The MOQ for standard specifications (such as 8mm, 18mm) is 1000 sheets. Customized thickness or size needs to be negotiated, and the MOQ is usually 2000 sheets.

Q: Can you provide FSC certification?

A: We support FSC-COC certification to ensure that the raw materials come from sustainably managed forests. The certificate is valid for 5 years and can be traced back to the specific forest farm.

Q: What are the environmental protection levels?

A: We provide E1 level (formaldehyde emission ≤0.124mg/m³), E0 level (≤0.05mg/m³) and ENF level (≤0.03mg/m³), which can be selected according to customer needs.

Q: What is the thickness tolerance range?

A: The thickness tolerance of 8mm is ≤±0.3mm, and the thickness tolerance of 18mm is ≤±0.5mm, which complies with the national standard GB/T 9846-2015.

Q: Can the size be customized?

A: Customized length, width and thickness are supported. The regular size is 1220mm×2440mm, and the maximum size can reach 1525mm×3050mm. The adaptability of the production equipment needs to be confirmed.