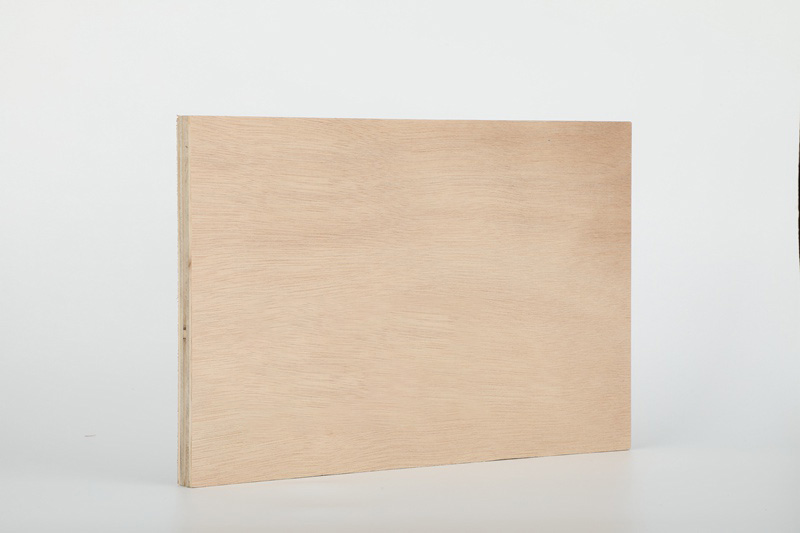

18mm Exterior Plywood

Please click the button below to contact us.

Introduction:18mm Exterior Plywood is a high-quality 18mm thick plywood for exterior use. It is made of multiple layers of wood veneer that are finely processed and glued together under high temperature and high pressure, and has excellent strength, stability and weather resistance.

Product Description

18mm Exterior Plywood is a high-quality 18mm thick plywood for exterior use. It is made of multiple layers of wood veneer that are finely processed and glued together under high temperature and high pressure, and has excellent strength, stability and weather resistance. The surface of this plywood presents the grain and texture of natural wood, and the common ones are light-colored birch or beech grain, giving people a rustic and natural visual experience. Whether it is used for formwork support in construction or as a tabletop material that bears heavy pressure in furniture manufacturing, it can provide reliable performance.

18mm Exterior Plywood Parameters

| Item | Parameter |

| Place of Origin | China |

| MOQ | 1000 pc |

| General Specifications | 5mm, 9mm, 12mm, 15mm, 18mm |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Regenerated Wooden Base |

| Transportation | By Sea/By land |

| Quality/Safety Certification | GB/T19001-2016/ISO9001:2015, Hi-tech Enterprise, Attestation of Chinese Environment Mark |

Characteristics of 18mm Exterior Plywood

High Hardness

18mm Exterior Plywood has a high hardness, with a Mohs hardness of 3.5, which makes it effectively resistant to wear and scratches in daily use. When used as a furniture tabletop, hard objects such as the edges of common metal furniture brackets and the bottom of glass cups frequently contact the tabletop, and it is not easy to leave obvious scratches on its surface. After professional testing, the scratch depth on the surface of the plywood is less than 0.05mm when a standard steel scratch test tool is used to apply a force of 500g, which hardly affects its aesthetics and normal use. This feature ensures that the product can still maintain a good appearance and performance after long-term use, reduces the frequency of replacement due to surface damage, and saves maintenance costs for users.

Excellent waterproof and moisture-proof performance

The plywood uses high-quality waterproof adhesives, which makes it have excellent waterproof and moisture-proof capabilities. Its water absorption rate is only 3%. In the immersion test, the thickness expansion rate of the plywood does not exceed 4% after 48 hours of immersion in water. Even in relatively humid environments, such as the rainy season in southern China, or when temporarily exposed to rain outdoors, it maintains its structural stability and strength. For building partitions or furniture used in high-humidity locations like basements and bathrooms, this waterproof and moisture-resistant property effectively prevents deformation and mold caused by water absorption, extending the product's lifespan.

Excellent Quality

18mm Exterior Plywood complies with the GB/T19001-2016/ISO9001:2015 quality management system certification, ensuring stringent control at every stage, from raw material procurement to production and processing. During the production process, each sheet of plywood undergoes at least five quality inspection steps, including visual inspection, dimensional measurement, and physical property testing. For example, dimensional measurement accuracy reaches ±0.5mm, ensuring that the product you purchase precisely meets design requirements in actual use, ensuring a perfect fit during cutting and assembly. This rigorous quality control system ensures a high degree of product consistency and reliability, allowing users to confidently use it in a variety of applications requiring high quality.

Precise thickness

18mm Exterior Plywood offers a precise 18mm thickness, which is ensured by advanced production processes and sophisticated equipment. On the production line, a laser thickness gauge is used to monitor each layer of wood veneer in real time to ensure that the thickness error of the veneer is controlled within ±0.2mm. After multiple layers of gluing and pressing, the thickness tolerance of the finished plywood does not exceed ±0.5mm. Such precise thickness is essential for fields such as construction and furniture manufacturing. In construction, as a formwork support material, precise thickness can ensure the flatness and dimensional accuracy after concrete pouring; in furniture manufacturing, precise thickness makes the fit between furniture parts tighter, improving the overall quality and stability of the furniture.

Excellent environmental performance

18mm Exterior Plywood has obtained the China Environmental Labeling Certification, which indicates that it strictly controls the use and emission of hazardous substances during the production process. Its formaldehyde emission is less than 0.05g/m³, which is far below the national limit of 0.124g/m³. When used indoors in furniture or for interior decoration, this plywood does not negatively impact indoor air quality, creating a healthy and safe living and working environment. For families with children, elderly people, or those with sensitive skin, choosing this environmentally friendly plywood can effectively reduce the risk of indoor environmental pollution and safeguard the health of their families.

Strong and Durable

This plywood exhibits high strength and toughness, with a bending strength of up to 120 MPa and a tensile strength of 80 MPa. This allows it to withstand significant weight and external forces without breaking or deforming. In practical applications, such as as steppings in construction scaffolding, it can easily support the weight of multiple construction workers and their tools without bending or breaking. Furthermore, repeated mechanical testing has proven that even after repeated impacts and heavy pressure, its internal structure remains intact, without delamination or cracking. This durability makes 18mm Exterior Plywood suitable for a variety of harsh working conditions and frequent use, making it an ideal choice for numerous projects requiring high-strength paneling.

Good dimensional stability

Thanks to the scientific production process and raw material selection, 18mm Exterior Plywood has good dimensional stability. Under the alternating dry and humid environment, the change rate of its length and width is less than 0.3%. In the actual test, the plywood was placed in an environment with a relative humidity of 30% - 90% for 30 days, and its dimensional change was measured. The results showed that there was almost no significant change in the size. This is very important for some architectural decoration and renovation projects that require precise size matching. For example, when decorating indoor walls, the decorative panels made of this plywood can ensure the flatness and uniformity of the gaps after installation, and will not cause bulging, cracking or enlarged gaps due to changes in environmental humidity, thereby ensuring the durability and beauty of the decorative effect.

High degree of customization

18mm Exterior Plywood accepts customized services, including customized sizes and printing personalized logos. Regarding size customization, plywood can be cut into various non-standard sizes based on specific user needs, with the smallest custom size reaching 100mm x 200mm, meeting the needs of small components for specialized projects. For logo customization, advanced screen printing technology enables precise imprinting of the user's logo onto the plywood surface, with an accuracy of ±0.1mm. This ensures that the product not only meets user performance requirements but also reflects the user's personalized aesthetic. Whether it's a corporate display stand for brand promotion or an individual creating furniture with their own unique logo, this customizable service provides users with a more personalized and flexible option.

Application scenarios of 18mm Exterior Plywood

Building construction

In the field of building construction, 18mm Exterior Plywood is an indispensable material. It is often used as a concrete formwork, and with its precise thickness and sturdy performance, it can withstand the huge pressure during concrete pouring. In actual construction, a piece of 18mm Exterior Plywood formwork with an area of 1.2m×2.4m can withstand a lateral pressure of up to 10kN per square meter, effectively ensuring the shape and dimensional accuracy of the concrete structure. At the same time, its excellent waterproof and moisture-proof performance ensures that the formwork is not easy to deform or damage in a humid construction environment, extending the service life of the formwork. Compared with traditional wooden formwork, the use of this plywood formwork can increase construction efficiency by about 30%, reduce the frequency of formwork replacement, and reduce construction costs. In addition, it can also be used for the pedals of building scaffolding, providing construction workers with a stable standing and operating platform to ensure construction safety.

Indoor decoration

In interior decoration, 18mm Exterior Plywood has a wide range of applications. It can be used to make interior partition walls. Due to its good dimensional stability and environmental performance, after the partition wall is installed, it can effectively prevent the wall from cracking and deformation caused by changes in environmental humidity, ensuring the beauty and comfort of the interior. In the construction of suspended ceilings, this plywood can be used as the base board of the suspended ceiling skeleton. Its strong performance can support the weight of various suspended ceiling materials, such as lighting, decorative panels, etc. After actual measurement, in the suspended ceiling with multiple heavy chandeliers (each weighing up to 5kg), 18mm Exterior Plywood was used as the base board. After long-term use, there was no sagging or cracking, ensuring the safety and stability of the suspended ceiling. At the same time, its waterproof and moisture-proof properties also make it suitable for the decoration of kitchens and bathrooms. As the backboard material of cabinets and bathroom cabinets in these areas, it can effectively resist the erosion of water vapor and extend the service life of cabinets and bathroom cabinets.

Furniture manufacturing

For the furniture manufacturing industry, 18mm Exterior Plywood is an ideal material for making heavy furniture. When making wardrobes, its strong and durable characteristics can withstand the weight of a large amount of clothing and hanging accessories. A standard-sized wardrobe (2m wide, 2.4m high, 0.6m deep) made of 18mm Exterior Plywood has been tested to bear more than 200kg of clothing and accessories without deformation or damage. Compared with ordinary density boards, this plywood has higher bending strength, which can ensure smoother opening and closing of wardrobe doors, and will not cause deformation of door frames due to the weight of the door. In addition, its waterproof and moisture-proof properties also make furniture more durable when used in humid environments, and will not cause problems such as board expansion and debonding due to moisture, providing users with more reliable and long-lasting furniture products.

Packaging and transportation

In the field of packaging and transportation, 18mm Exterior Plywood can be used to make high-quality packaging boxes. For some heavy machinery and equipment or fragile precision instruments, packaging materials with high strength and good protective properties are required during transportation. The packaging boxes made of this plywood have a sturdy structure that can effectively resist collision and extrusion during transportation. After actual testing, a packaging box (1m×1m×1m) made of 18mm Exterior Plywood can remain intact and the goods inside are not damaged after bearing a pressure 5 times its own weight (about 1000kg). At the same time, the waterproof performance of the plywood can prevent rainwater from penetrating into the interior of the packaging box, protecting the goods from the influence of humid environment. Compared with ordinary corrugated cardboard packaging boxes, its protective performance is improved several times, which greatly reduces the risk of damage to goods during transportation. It is the preferred material for packaging high-value goods.

Shipbuilding

Shipbuilding is another important application area of 18mm Exterior Plywood. In the manufacture of ship decks and cabin internal structures, this plywood plays an important role. Since ships are in a humid and corrosive marine environment for a long time, the waterproof, moisture-proof and corrosion-resistant properties of the material are extremely high. After professional testing, 18mm Exterior Plywood showed no obvious corrosion after 300 hours of testing in the corrosion resistance test in a salt spray environment. In practical applications on ship decks, it can withstand the weight of crew members and equipment, as well as the external forces caused by the impact of waves. Its sturdy performance allows the deck to remain stable during long voyages without cracking or deformation. At the same time, the dimensional stability of the plywood ensures the precise assembly of the internal structure of the ship's cabin, improving the overall quality and safety of the ship.

Sports equipment manufacturing

In the manufacture of sports equipment, 18mm Exterior Plywood has also been widely used. For example, when making the base of fitness equipment, the sturdiness and durability of the plywood can withstand the weight of the fitness equipment itself and the various external forces generated by the user during exercise. A typical fitness equipment base (size 0.5m×0.5m×0.2m) is made of 18mm Exterior Plywood and can withstand a weight pressure of more than 500kg, ensuring the stability and safety of the fitness equipment during use. At the same time, its waterproof and moisture-proof properties also allow sports equipment to be used normally in various indoor and outdoor environmental conditions, without being damaged by moisture, extending the service life of the equipment. In the construction of sports venues, such as the support structure of basketball stands, this plywood can provide sufficient strength and stability to ensure the safety of athletes during use. It is an indispensable high-quality material in the manufacture of sports equipment.

Maintenance methods of 18mm Exterior Plywood

Daily Cleaning

For daily cleaning of 18mm Exterior Plywood, we recommend wiping with a soft, clean, damp cloth. Avoid using harsh cleaning tools, such as steel wool or scouring pads, to avoid scratching the surface. You can use a mild detergent solution diluted in water at a ratio of 1:20 (detergent:water). Gently wipe the surface of the board with a damp cloth. Finally, wipe off any detergent residue with a clean, damp cloth and allow to air dry. Regular cleaning removes dust, stains, and microorganisms, maintaining the appearance and hygiene of the board. A thorough cleaning is generally recommended once a week. For high-use areas, such as kitchens and bathrooms, more frequent cleaning may be appropriate to ensure it remains in good condition.

Moisture-Proofing Treatment

To protect 18mm Exterior Plywood from moisture, appropriate moisture-proofing measures should be taken. When storing indoors, it is best to place the board in a well-ventilated, dry area, away from direct contact with the floor or walls. Use wooden blocks to elevate the board, keeping it at least 100mm above the ground. When storing plywood, the relative humidity should be maintained between 30% and 60%, and the temperature should be maintained between 15°C and 30°C. During humid seasons, a dehumidifier can be used to reduce indoor humidity. For example, during the rainy season in southern China, using a dehumidifier to keep indoor humidity below 50% can effectively prevent moisture absorption, swelling, and mold growth. Additionally, applying a layer of waterproof paint to the edges and back of the plywood can further enhance its moisture resistance. For plywood already installed in buildings or furniture, a desiccant, such as silica gel, can be placed around the plywood and replaced regularly to absorb moisture and protect it from moisture.

Avoid impact with hard objects

During the use and storage of 18mm Exterior Plywood, avoid impact with hard objects. When handling plywood, handle it with care and avoid collision with other hard objects. If heavy objects are placed on the plywood surface, it is recommended to place soft material, such as rubber or foam pads, between the object and the plywood surface to distribute the pressure and reduce impact. During construction, avoid direct impacts on plywood used as formwork with tools such as hammers and wrenches. When using furniture, avoid placing sharp objects directly on the surface, such as high heels or furniture with pointed soles. These measures can effectively prevent dents and cracks on the surface, extending the lifespan of the board and maintaining its structural integrity and aesthetics.

Regular Inspection

Regular inspection of 18mm exterior plywood is crucial to ensuring its long-term stability. Inspections should include checking for scratches, bumps, bulges, and delamination. For plywood used as structural material, special attention should be paid to checking joints for signs of looseness or cracking. A comprehensive inspection is recommended at least quarterly. Any problems detected should be promptly repaired. For example, minor scratches on the surface can be repaired using wood wax oil that's a similar color to the board. Apply an appropriate amount of wood wax oil based on the size and depth of the scratch and rub it evenly with a clean cloth, allowing it to penetrate the scratch thoroughly. After 2-3 repeated applications and wiping, the scratch should be largely concealed, restoring the board's beautiful appearance. For larger damage, such as delamination or severe bulging, contact a professional repairer immediately for evaluation and repair to prevent further damage and affect the board's normal use.

Protecting against direct sunlight

Prolonged exposure to direct sunlight can cause fading and aging of the 18mm Exterior Plywood surface. Therefore, avoid exposing the board to strong sunlight. When using the board outdoors, use an awning or shade net to shade the board. Indoors, avoid placing the board near windows in direct sunlight. If direct sunlight is unavoidable, use curtains or blinds to control the light. In actual testing, after one summer of outdoor use, panels shaded by awnings exhibited only 15% of their surface color change compared to unshaded panels, effectively maintaining their appearance. Furthermore, direct sunlight can increase the surface temperature of panels, causing rapid evaporation of moisture within them, which can lead to deformation and other problems. Therefore, while shielding panels from direct sunlight, this also indirectly protects their structural stability.

More Details about 18mm Exterior Plywood