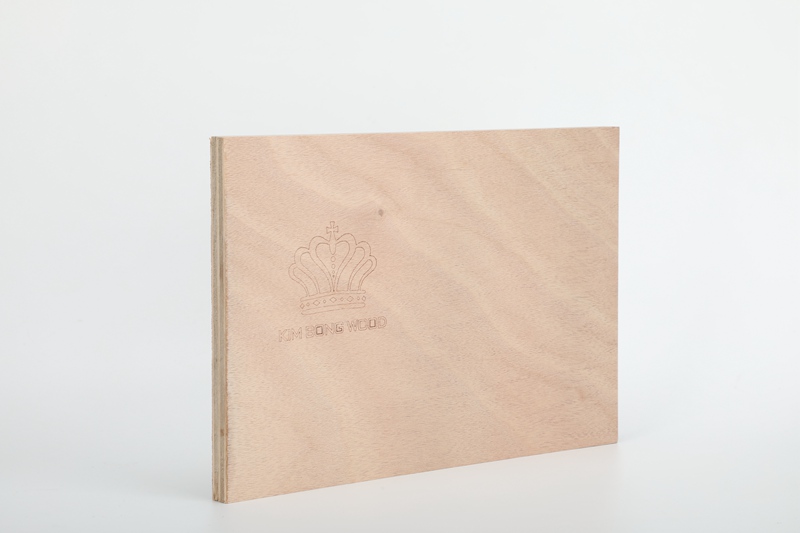

Multi Layered Plywood

Please click the button below to contact us.

Introduction:Multi-layered plywood is a kind of artificial board made of three or more layers of thin wood boards (veneers) stacked vertically with adhesives and pressed under high temperature and high pressure.

Product Description

Multi-layered plywood is a kind of artificial board made of three or more layers of thin wood boards (veneers) stacked vertically with adhesives and pressed under high temperature and high pressure. The number of layers is usually an odd number (such as 3 layers, 5 layers, 7 layers), and the fiber directions of each layer of veneer are perpendicular to each other, forming a stable structure. Multi-layer plywood combines the natural texture of wood and the stability of artificial boards. It is widely used in furniture manufacturing, architectural decoration, packaging and transportation, etc., replacing traditional solid wood materials.

Multi-layer Fumiture Board Parameters:

| Item | Parameter |

| Place of Origin | China |

| MOQ | 1000 pc |

| General Specifications | 5mm, 9mm, 12mm, 15mm, 18mm |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Regenerated Wooden Base |

| Transportation | By Sea/By land |

| Quality/Safety Certification | GB/T19001-2016/ISO9001:2015, Hi-tech Enterprise, Attestation of Chinese Environment Mark |

Features

Basic parameters:

Thickness range: 5mm, 9mm, 12mm, 15mm, 18mm (common specifications).

Size specifications: standard size 1220mm×2440mm, the maximum custom size can reach 2440mm×6000mm.

Density: 600-700kg/m³.

Moisture content: 8%-12% (in line with national standards).

Bonding strength: ≥0.7MPa (GB/T 9846-2015 standard).

Formaldehyde emission: E0 grade ≤0.5mg/L, E1 grade ≤1.5mg/L.

Core features:

1. High stability:

The staggered laminated structure makes the board less likely to deform under temperature and humidity changes, and the dimensional stability is better than solid wood.

Bending strength ≥30MPa, suitable for large span or load-bearing structures.

2. High strength:

The impact resistance is 2-3 times that of solid wood, the tensile strength is ≥40MPa, and the compressive strength is ≥35MPa.

The more layers (such as 9 layers, 12 layers), the higher the strength, which is suitable for high-load scenes.

3. Weather resistance:

Excellent water resistance, no delamination after 72 hours of boiling water boiling test, suitable for humid environments.

Weather-resistant plywood can withstand extreme temperatures from -40℃ to 80℃, suitable for outdoor scenes.

4. Environmental protection:

Environmentally friendly adhesives (such as phenolic resin, urea-formaldehyde resin) are used, and the formaldehyde emission meets the E0 grade standard.

The recycling rate is ≥95%, which meets the requirements of sustainable development.

5. Processability:

Supports cutting, drilling, engraving, hot pressing and other processes, and the minimum processing radius can reach 1.5 times the thickness of the board.

The surface can be covered with veneer, PVC film, melamine paper and other finishing materials to meet diverse design needs.

6. Economic efficiency:

Compared with solid wood, the raw material utilization rate of multi-layer plywood is increased by 30%, and the cost is reduced by 20%-30%.

The service life is up to 10-15 years, and the maintenance cost is low.

Application scenarios

1. Furniture manufacturing

Scenario: office desks, conference tables, bookcases, wardrobes, bed boards, etc.

Solution:

Boards with a thickness of 12mm-18mm are used for load-bearing structures, with a bending strength of ≥35MPa to avoid deformation after long-term use;

The surface is covered with veneer or melamine paper to achieve imitation of solid wood texture and reduce material costs;

Lightweight design (density 650kg/m³) for easy transportation and installation. 2. Architectural decoration

Scenario: partition walls, ceilings, floor substrates, door and window casings.

Solution:

9mm-12mm thick boards are used for partition walls, with a 40% improvement in sound insulation and a fire rating of B1;

Water-resistant plywood (passed the 72-hour boiling water test) is used in humid environments such as bathrooms and kitchens;

Bendable (minimum curvature radius 50mm), suitable for arc or special-shaped designs.

3. Packaging and transportation

Scenario: heavy equipment packaging boxes, pallets, container bottom plates.

Solution:

15mm-18mm thick boards have an impact strength of ≥50kJ/m², protecting precision equipment from transportation vibration damage;

Surface moisture-proof treatment (waterproof coating), water resistance increased by 60%;

Recyclable, reducing the cost of packaging waste treatment.

4. Vehicle and shipbuilding

Scenario: car interiors, cabin partitions, deck base.

Solution:

Flame-retardant plywood (combustion performance B1 grade) is used in public transportation to reduce the risk of fire;

Weather-resistant plywood is resistant to salt spray corrosion and has a service life of more than 8 years;

Lightweight design (60% lighter than steel) improves fuel efficiency.

5. Exhibition and display

Scenario: booths, display racks, background boards, props production.

Solution:

5mm-9mm thick boards are easy to cut and splice, suitable for complex shapes;

The surface can be sprayed or covered with advertising film, with a color reproduction of ≥95%;

Modular design (size 1220mm×2440mm) is convenient for quick construction and disassembly.

6. Agriculture and gardening

Scenario: greenhouse skeleton, flower box, nursery bed, fence.

Solution:

Anti-corrosion plywood (ACQ anti-corrosion treatment) has a 50% increase in weather resistance and a service life of ≥10 years;

12mm thick boards have a load-bearing capacity of ≥200kg/m², suitable for heavy flower boxes;

Environmentally friendly and non-toxic, in line with agricultural product planting safety standards.

Cleaning and Maintenance Guide

Daily Cleaning:

Use a soft cloth or vacuum cleaner to remove dust from the surface, and avoid using detergents containing acid or alkali.

Grease can be wiped with a neutral detergent (such as dishwashing liquid) diluted, then washed with clean water and dried.

Protective Measures:

Avoid long-term exposure to direct sunlight to prevent surface fading or cracking.

Surface scratches ≤0.2mm deep can be repaired with fine sandpaper (600 mesh) and then coated with wood wax oil.

Repair and Replacement:

Partial cracking or delamination requires replacement of the entire board, and the interface is bonded with epoxy resin glue (shear strength ≥20MPa).

Aged boards (surface peeling, glue layer falling off) need to be replaced as a whole to avoid safety hazards.

Storage Conditions:

Unused boards should be stored in a dry and ventilated environment (humidity ≤60%), at a temperature of 5℃-35℃, and avoid heavy pressure.

After opening, they must be used within 3 months, and the remaining parts should be wrapped and sealed with moisture-proof film.

FAQs

Q1: Is multi-layer plywood environmentally friendly?

A: It meets the E0 standard, formaldehyde emission ≤0.5mg/L, and recyclability ≥95%.

Q2: Can the size and thickness be customized?

A: Customization is supported, with a maximum size of 2440mm×6000mm and a thickness of 5mm-18mm.

Q3: How is the water resistance?

A: Water-resistant plywood has passed the 72-hour boiling water test without delamination and is suitable for humid environments.

Q4: How long is the service life?

A: 10-15 years for indoor use and 8-10 years for outdoor use (depending on environmental differences).

Q5: Does it support bending?

A: It supports hot bending, with a minimum curvature radius of 50mm (for boards with a thickness of less than 12mm).