Can I Use Plywood Instead Of A Bunkie Board?

When setting up a bed frame, particularly for platform beds, trundle beds, or bunk beds, a bunkie board is often used to provide support for the mattress. However, many homeowners and furniture makers wonder: can plywood be used instead of a bunkie board?

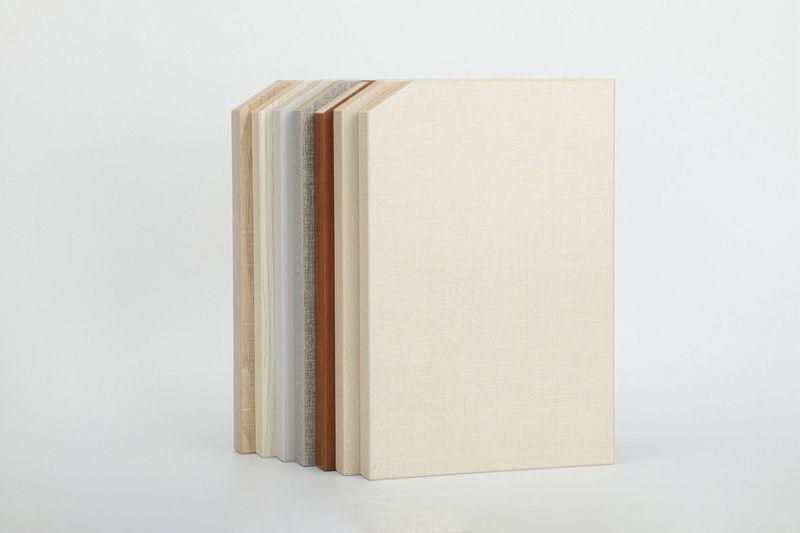

The answer is yes — plywood can effectively replace a bunkie board if selected and installed properly. It’s strong, affordable, and provides excellent mattress support. For manufacturers like KIM BONG, which specializes in plywood, Particle Board, and multi-layer Ecological Board, plywood has long been a reliable solution for both furniture production and bed foundation systems. Let’s explore why plywood works as an excellent bunkie board alternative and how to choose the right type.

1. What Is a Bunkie Board?

A bunkie board is a thin, supportive layer that sits between the bed frame and the mattress. It provides a solid foundation without adding much height, making it ideal for:

Platform beds

Bunk beds

Daybeds

Adjustable beds

Traditionally, bunkie boards are made of solid wood slats or particle board wrapped in fabric. However, many modern furniture producers prefer plywood because it provides the same level of support — and sometimes more — while being lighter and more cost-effective.

| Comparison | Traditional Bunkie Board | Plywood Alternative |

|---|---|---|

| Structure | Wooden slats or particle board | Cross-laminated wood veneer layers |

| Support Level | High | High to very high |

| Durability | Good | Excellent |

| Cost | Moderate | Economical |

| Environmental Grade | E1–E0 | E0 available (KIM BONG) |

2. Why Plywood Can Be Used Instead of a Bunkie Board

Plywood is a multi-layer engineered wood panel made by bonding thin layers of wood veneers with the grain running alternately at 90 degrees. This design gives plywood exceptional strength, flexibility, and resistance to warping, which are all qualities required for mattress support.

A. Structural Strength and Stability

The cross-laminated layers of plywood distribute weight evenly, preventing sagging over time.

A 12mm–18mm thick plywood sheet can easily handle the weight of a standard mattress and sleeper.

It also resists bending and cracking better than single-layer materials.

KIM BONG’s multi-layer plywood undergoes high-temperature hot pressing and uniform glue coating, ensuring excellent nail-holding strength and dimensional stability, even after years of use.

B. Uniform and Flat Surface

Plywood provides a completely flat base, which helps keep the mattress level.

A stable surface prevents sagging in foam or hybrid mattresses, improving comfort and extending mattress life.

KIM BONG’s super-flat lamination technology ensures that every plywood sheet maintains a precise surface, ideal for modern bedding systems.

C. Custom Thickness and Size Options

Unlike standard bunkie boards, plywood can be customized to suit any bed frame.

Manufacturers can cut panels to exact bed dimensions and select the right thickness based on mattress type:

| Mattress Type | Recommended Plywood Thickness |

|---|---|

| Foam or memory mattress | 12mm–15mm |

| Hybrid mattress | 15mm–18mm |

| Spring mattress | 18mm–20mm |

D. Cost and Efficiency Advantage

Plywood offers the same functional benefits as a bunkie board but at a lower cost. It’s easier to transport, cut, and install. For large-scale furniture manufacturers, this means:

Reduced material waste

Lower production cost

Simplified assembly and packaging

With KIM BONG’s ISO9001-certified production system, our plywood panels are produced efficiently while maintaining consistent quality, strength, and environmental performance.

3. Advantages of KIM BONG Plywood for Bed and Furniture Use

At Kaiping Hanbang Wood Industry Co., Ltd., we specialize in high-quality plywood, particle board, and Multi-Layer Ecological Board, all available in E0-grade environmental standards.

Our plywood is particularly suitable for bunkie board replacement, furniture panels, and cabinet structures due to its stability and eco-safety.

A. Technical Excellence

KIM BONG applies four key technologies that enhance the strength and performance of every panel:

Ultra-flat pressing technology – Ensures perfect surface evenness.

Uniform glue coating technology – Improves bonding strength and density.

High-temperature and high-pressure lamination – Increases core stability and durability.

Formaldehyde-free bonding process – Reduces emissions for healthier indoor use.

These processes result in a panel that’s denser, stronger, and more environmentally friendly than ordinary boards.

B. E0-Grade Environmental Performance

All KIM BONG plywood products comply with E0 environmental standards, ensuring ultra-low formaldehyde emissions — perfect for bedroom furniture.

| Environmental Grade | Formaldehyde Emission (mg/L) | Application |

|---|---|---|

| E2 | ≤5.0 | Industrial applications |

| E1 | ≤1.5 | Standard furniture |

| E0 (KIM BONG) | ≤0.5 | Premium indoor use |

This guarantees a healthy sleeping environment and meets export standards for Europe and Asia-Pacific markets.

C. Versatile Applications

Beyond bunkie board alternatives, KIM BONG plywood is widely used in:

Bedroom furniture (bed frames, wardrobes, nightstands)

Cabinets and shelving

Decorative wall panels

multi-layer ecological boards for interior design

Each sheet is engineered for long-term durability and high bonding strength, meeting both aesthetic and structural needs.

D. Long-Term Durability

Plywood used as a bunkie board is expected to last over 10 years under normal conditions.

With KIM BONG’s advanced adhesive and hot-pressing process, the panels maintain tight bonding even under repeated pressure.

This makes them ideal for platform beds or bunk systems where thin yet strong base panels are essential.

4. How to Use Plywood Safely as a Bunkie Board

Using plywood as a mattress base requires proper installation and care to maintain durability and mattress comfort.

A. Choose the Right Thickness

Select a thickness based on bed frame design:

For slatted frames, use 18mm plywood for added strength.

For solid platforms, 12–15mm thickness is usually enough.

Avoid extremely thin sheets, as they may bend or break under concentrated weight.

B. Ensure Proper Ventilation

Plywood blocks airflow more than slats. To prevent mold or moisture buildup:

Drill several small ventilation holes across the surface.

Use breathable bed linens or an anti-moisture mat under the mattress.

C. Protect the Edges

Seal all edges with a protective coating or veneer tape to prevent moisture absorption and splintering.

KIM BONG’s multi-layer ecological boards already feature protective edge structures and surface lamination, offering a ready-to-use alternative.

D. Support Frame Alignment

Ensure that the plywood rests evenly on the bed frame.

Use supportive beams or a central spine to prevent sagging, especially for larger sizes such as queen or king beds.

| Bed Type | Recommended Support Setup |

|---|---|

| Twin / Single | 12mm plywood + slat base |

| Queen | 15mm plywood + central beam |

| King | 18mm plywood + dual central supports |

Conclusion

So, can you use plywood instead of a bunkie board?

Absolutely. With the right thickness, ventilation, and edge protection, plywood provides the same — and sometimes better — support as a traditional bunkie board.

At KIM BONG, we produce premium E0-grade plywood using advanced lamination and bonding technologies, ensuring exceptional strength, flatness, and environmental safety.

Our plywood panels are widely used in furniture manufacturing, bed systems, and decorative applications, serving clients worldwide.

If you’re looking for a reliable, cost-effective, and eco-friendly solution for your bed or furniture project, KIM BONG plywood is the smart alternative.

KIM BONG — High-Quality Plywood and Ecological Panels for a Better Living Environment.

Stronger. Smoother. Smarter.

Previous: Is OSB Board Fire Resistant?