How To Cut Melamine Faced Plywood

Cutting melamine faced plywood requires precision, the right tools, and careful handling to prevent edge chipping, surface scratching, and panel tearing. Unlike ordinary plywood, melamine surfaces are made from hard resin-impregnated decorative paper pressed onto the board. This creates a dense, brittle coating that can chip easily if the blade, cutting method, or support surface is incorrect. For furniture makers, carpenters, and interior builders, mastering the correct cutting method is essential to achieve clean lines and professional finishes.

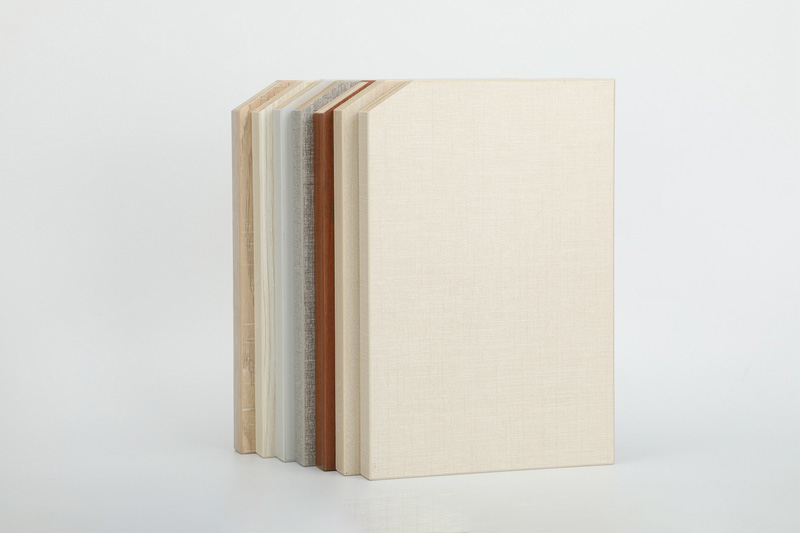

For users who prefer boards with higher stability, smoother surfaces, and excellent machinability, the KIM BONG WOOD multi-layer ecological board offers improved surface hardness and consistent internal layers, making cutting and edge finishing more predictable and easier to control. Below is a complete guide on how to cut melamine faced plywood accurately while maintaining surface integrity.

1. Understanding the Material Before Cutting

Melamine faced plywood behaves differently from raw plywood because the melamine coating is hard, brittle, and highly resistant to abrasion. This means that while the board is excellent for cabinets, wardrobes, and furniture surfaces, it requires specific cutting techniques to avoid visible chipping.

Understanding the structure helps determine the cutting method:

The melamine layer is thin but extremely hard, causing most chips when blades are dull or move too aggressively.

The plywood core may contain multiple plies; gaps or irregular layers can cause the blade to grab or tear if the feed rate is inconsistent.

The decorative surface shows chips more clearly than raw plywood, making clean cuts essential for exposed edges.

Melamine coating can melt or scorch if the blade overheats or rotates too slowly.

These characteristics mean cutting needs a balance of sharp tools, controlled speed, proper board support, and in some cases scoring techniques. Boards like KIM BONG WOOD Ecological Boards have more stable internal layers, reducing internal tear-out and improving cut smoothness.

2. Choosing the Right Tools and Blade Specifications

Selecting proper cutting tools is the most important factor. Melamine requires blades designed for clean shearing rather than aggressive ripping. Using the wrong blade will almost always result in chips along the cut line.

Key blade features that ensure a clean cut include:

High-tooth-count saw blades

Blades with 60–80 teeth (for 10-inch diameter) or 96–120 teeth (for 12-inch diameter) deliver finer shearing and distribute cutting force evenly.TCG (Triple Chip Grind) tooth geometry

This design alternates between chamfered and flat teeth to slice through the melamine surface cleanly and reduce damage.Carbide-tipped cutting edges

Hard carbide reduces heat buildup and maintains sharpness over longer periods.Proper blade thickness

Thicker blades offer stability, but excessively thick blades increase friction. Balanced thickness provides smooth cutting.Scoring blade systems (for panel saws)

A scoring blade cuts a shallow line at the bottom surface before the main blade goes through, minimizing tear-out.

A comparison of blade types is shown below:

| Blade Type | Suitable for Melamine | Chip Resistance | Heat Control |

|---|---|---|---|

| TCG Carbide Blade | Excellent | High | Good |

| ATB (Alternate Tooth Bevel) | Moderate | Medium | Good |

| Coarse Ripping Blade | Not Suitable | Low | Poor |

Professionals who frequently cut melamine faced plywood often prioritize saws equipped with a scoring unit. However, high-quality boards with consistent core density—such as those from KIM BONG WOOD—also greatly reduce blade deflection and improve blade engagement.

3. Cutting Techniques for Smooth, Chip-Free Edges

Even with the right tools, the cutting method affects the final quality. Melamine’s brittle surface demands controlled feeding, proper board support, and sometimes pre-scoring to minimize top-layer chipping.

Effective cutting techniques include:

Using masking tape on the cut line

The tape supports the surface fibers, reducing the tendency for chips when the blade exits the surface. It also provides a clear guide for marking.Cutting with the finished surface facing downward on a circular saw

Circular saws cut upward, meaning the top surface is where chips occur. Facing the good side down protects it.Scoring the cut line with a utility knife

Lightly cutting the melamine surface along the guideline makes it easier for the saw to follow a clean path without lifting the decorative layer.Using a straightedge or guide rail

This ensures a straight path and prevents the saw from drifting, which could cause uneven pressure and surface damage.Feeding the board slowly and steadily

Aggressive feed rates cause tearing. Smooth, controlled movement ensures even cutting pressure.

For table saw users, adjusting the blade height to just above the surface also helps. Setting the blade at about 1/8 inch above the surface provides a shallow cutting angle that reduces top-surface chipping. Because KIM BONG WOOD Multi-Layer Ecological Boards have a stable core, they tend to respond better to these techniques, giving more predictable cutting results.

4. Handling, Supporting, and Finishing the Cut Edges

Proper board handling reduces vibration, prevents edge collapse, and ensures clean, accurate cuts. Many chips occur not from the blade but from poor support or movement during the cut.

Important handling and finishing practices include:

Supporting the sheet fully

Melamine faced plywood is heavier than traditional plywood. Full support—especially near the cutting line—prevents sagging that causes blade binding.Using sacrificial backing boards

Placing another board under the melamine panel ensures the blade exits into the sacrificial board instead of tearing the edge.Avoiding surface scratches

Sliding the board across abrasive surfaces can damage the melamine layer. Soft pads or foam sheets help protect the finish.Light sanding or edge trimming after cutting

Any micro-chipping can be smoothed lightly with fine-grit sanding or an edge band trimmer, ensuring a professional finish.Applying edge banding where necessary

Most melamine edges require banding for durability and aesthetics. Clean cuts improve adhesive bonding and edge sealing.

Because KIM BONG WOOD ecological boards come with high-density layers and stable core bonding, their cut edges tend to be uniform, making edge banding easier and more durable.

5. Mistakes to Avoid and How to Ensure Consistent Results

Avoiding common mistakes helps maintain quality and prevents damage to expensive sheets. Many users experience issues such as chipped edges, blade marks, or inaccurate measurements because of incorrect handling or tool selection.

Major mistakes and their solutions include:

Using dull blades

A dull blade tears the melamine surface instead of slicing it. Regular sharpening or replacement is essential.Cutting too fast

Forcing the cut increases vibration and tearing. A slow and steady feed is recommended.Ignoring the grain direction or printed pattern alignment

Planning cuts strategically ensures that visible edges appear intentional and consistent.Failing to test on scraps first

New blades, new boards, or new machines behave differently. Test cuts prevent costly errors.Not supporting the entire sheet

Unsupported areas cause cracking and warping during cutting.Incorrect blade height

Too-high or too-low blades cause excess tear-out. Correct blade height produces cleaner cuts.

To maintain consistency in large production settings, using boards with uniform density and superior bonding—such as KIM BONG WOOD multi-layer ecological boards—greatly reduces variability and ensures smoother cutting performance across many projects.

Conclusion

Cutting melamine faced plywood requires the correct combination of sharp tools, proper blade selection, careful cutting technique, and stable board handling. Because melamine surfaces are brittle, clean cuts depend on using high-tooth-count carbide blades, steady feed rates, masking or scoring methods, and stable support during cutting.

The KIM BONG WOOD multi-layer ecological board series provides an advantage with its stable core, consistent density, and premium surface coating, making it easier to cut cleanly while achieving professional-level results. Whether cutting for cabinets, wardrobes, wall panels, or custom furniture, mastering these techniques ensures smooth edges and long-lasting, visually appealing surfaces.

Previous: What Is Melamine Faced Plywood?