What Is Melamine Faced Plywood?

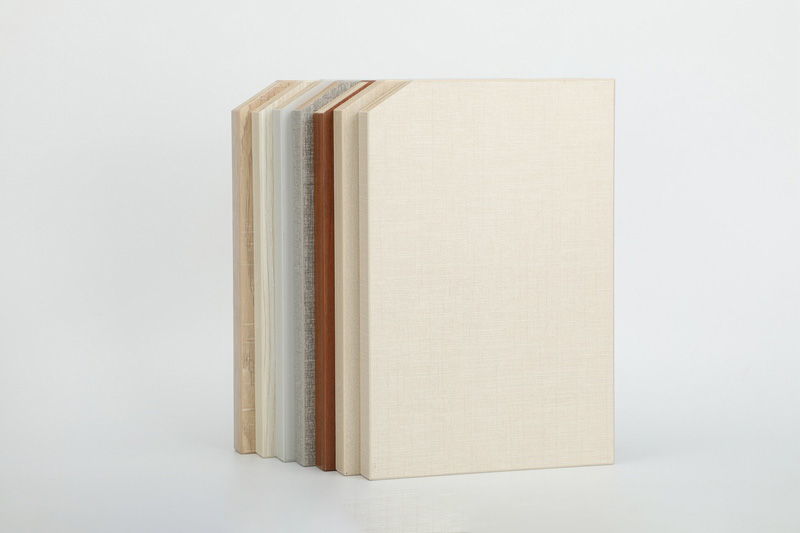

Melamine faced plywood is a type of engineered wood panel that combines the strength of plywood with a melamine resin–impregnated decorative surface. The melamine layer provides a hard, scratch-resistant, moisture-resistant, and visually consistent finish, making it one of the most popular materials for cabinets, wardrobes, interior furniture, wall panels, and custom carpentry. Unlike raw plywood that requires paint or varnish, melamine faced plywood is pre-finished, allowing builders and manufacturers to achieve a ready-to-install surface with high durability and uniform appearance.

In modern home and commercial construction, melamine faced plywood is valued for its stability, low emissions, and excellent machinability. Products such as the KIM BONG WOOD multi-layer ecological board elevate this category further by offering E0-grade environmental performance, thickened core layers, premium imported wood veneers, and advanced formaldehyde-removal technology.

1. Understanding the Structure and Composition of Melamine Faced Plywood

Melamine faced plywood is built from two key components: a plywood core made of multiple thin wood layers and a melamine paper surface impregnated with thermosetting resin. When pressed together under high temperature and high pressure, the melamine coating becomes permanently fused to the plywood, creating a dense and smooth exterior surface.

To understand its structure clearly:

The core consists of cross-laminated wood veneers that give the board dimensional stability and reduce warping. The alternating grain of each layer improves strength in all directions.

The melamine surface is made from decorative paper soaked in melamine resin. When cured, it forms an extremely hard outer shell that is resistant to scratches, moisture, stains, and daily wear.

The combination of the strong interior and durable exterior creates a board that requires no additional surface finishing.

Premium melamine faced plywood, such as the multi-layer Ecological Board from KIM BONG WOOD, typically includes features like thickened fiber layers, reinforced bonding, and precise sanding to achieve a smooth and consistent surface. Advanced board structures undergo cold press, hot press, sanding, and formaldehyde-removal processing, making them stable and safer for indoor use.

2. Key Characteristics That Define Melamine Faced Plywood

The melamine layer contributes to a number of performance advantages that distinguish melamine faced plywood from ordinary plywood, MDF, or Particle Board. These properties make it ideal for furniture manufacturing and decorative interior construction.

Several defining characteristics include:

High surface hardness

The cured melamine resin forms a protective shell that is much harder than paint or laminate film, resisting scratches and abrasions in daily use.Moisture resistance

Melamine surfaces do not absorb water, allowing the board to withstand humid environments such as kitchens and bathrooms.Color and pattern consistency

From woodgrains to solid colors, melamine finishes remain uniform across large production batches.Chemical resistance

Melamine layers tolerate cleaning products, alcohol, and common household chemicals.Heat stability

The surface remains stable under moderate heat, preventing bubbling or discoloration.

KIM BONG WOOD ecological boards use a reinforced multi-layer core, imported wood veneers, and 5A-grade base materials to improve internal stability, edge integrity, and long-term performance. Their environmental rating reaches E0, meaning extremely low formaldehyde emissions that support healthy indoor living.

3. Applications of Melamine Faced Plywood in Modern Furniture and Interior Construction

Melamine faced plywood is widely used because it combines durability, aesthetics, and efficiency. Manufacturers, designers, and builders rely on it for furniture components and interior décor where attractive appearance and high performance are required.

Common application areas include:

Cabinets and wardrobes

Its smooth and scratch-resistant surface makes it ideal for kitchen cabinets, bedroom wardrobes, and storage systems.Shelving and bookcases

The board maintains shape under load and provides a clean, decorative finish.Interior wall paneling

Melamine surfaces offer modern decorative effects suitable for residential and commercial spaces.Office furniture

Desks, partitions, drawers, and workstations often use melamine faced plywood due to its strength and easy maintenance.Bathroom and laundry furniture

The moisture-resistant surface withstands humid environments, especially when combined with high-density ecological core materials.

KIM BONG WOOD boards are specifically engineered to support these uses, with thickened structure, low-odor performance, and tightly bonded layers that withstand machining, cutting, edge banding, and installation.

4. Advantages Compared with Other Wood Panel Materials

Melamine faced plywood competes with materials such as MDF, particle board, solid plywood, and laminated boards. Its performance advantages make it a preferred option for high-quality furniture manufacturing.

Below is a comparison to highlight its strengths:

| Property | Melamine Faced Plywood | MDF | Particle Board |

|---|---|---|---|

| Surface Durability | High | Medium | Low |

| Moisture Resistance | Strong | Medium | Low |

| Structural Strength | High | Medium | Low |

| Screw Holding Power | Strong | Medium | Weak |

| Weight | Moderate | Heavy | Light |

| Environmental Grade | E0–E1 | Varies | Varies |

| Ideal Uses | Cabinets, furniture, interior décor | Paint-grade furniture | Low-cost furniture |

Key advantages include:

Superior strength from cross-laminated layers

Greater durability from melamine resin coating

Faster production because no painting or polishing is required

Lower formaldehyde emissions when using ecological cores

Better dimensional stability under load or temperature changes

KIM BONG WOOD Multi-Layer Ecological Boards stand out with imported core veneers, 30-day natural drying, double artificial drying cycle, and strict quality inspection processes that reduce internal voids and ensure consistent strength.

5. Environmental Performance and Why Ecological Boards Are Preferred

As indoor air quality and environmental safety become essential for families and commercial projects, melamine faced plywood is increasingly evaluated based on its emissions, adhesives, and overall sustainability. Ecological plywood products offer significantly lower formaldehyde release and are processed with cleaner technologies.

Environmental advantages include:

Low formaldehyde emission levels

Ecological boards like those from KIM BONG WOOD reach E0 grade, one of the strictest indoor environment standards.Advanced formaldehyde-removal technology

High-temperature sealed drying and dust-extraction techniques help remove residual volatile compounds from the board.Safer adhesives and resins

High-quality resins reduce odor, emissions, and long-term chemical release.Optimized drying and moisture control

Boards are dried multiple times to maintain stable moisture content, preventing deformation during use.Cleaner production processes

Fewer coatings and no oil-based paints reduce VOC emissions during manufacturing.

This makes KIM BONG WOOD ecological boards an excellent choice for families seeking healthy, odor-free living environments, especially in wardrobes, cabinets, children's rooms, and full-house furniture customization.

Conclusion

Melamine faced plywood is a durable, attractive, and efficient panel material that combines a strong plywood core with a scratch-resistant melamine coating. It is ideal for modern furniture, cabinetry, interior wall panels, and commercial décor because of its high strength, consistent appearance, and resistance to moisture and wear.

The KIM BONG WOOD multi-layer ecological board expands these benefits by providing improved structural stability, premium imported core materials, strict environmental standards, and advanced surface technologies. This makes it a reliable choice for customers seeking high-quality, long-lasting, and environmentally safe furniture materials for residential and commercial projects.

Previous: How To Choose Plywood for Furniture