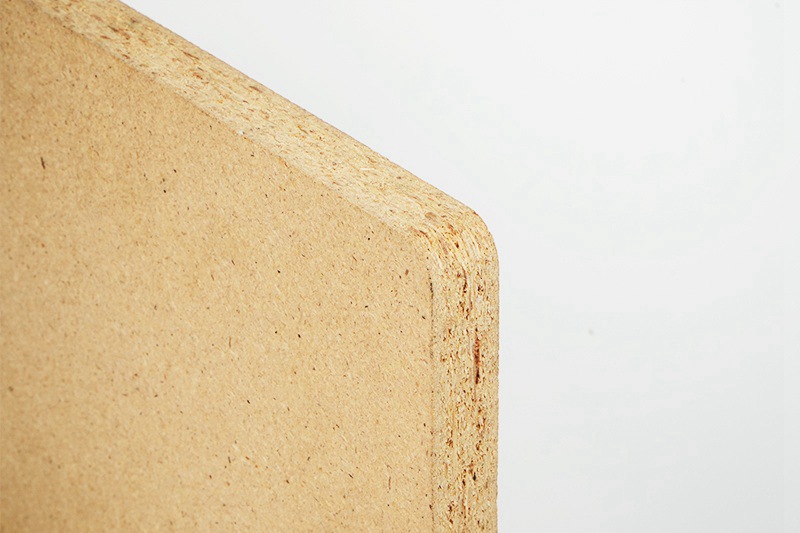

OSB Decorative Particle Board

Please click the button below to contact us.

Introduction:Decorative Particle Board is a decorative board made of wood particles through special processing. This board presents the texture and color of natural wood, and the surface is finely processed, with unique texture and beauty.

Product Description

Decorative Particle Board is a decorative board made of wood particles through special processing. This board presents the texture and color of natural wood, and the surface is finely processed, with unique texture and beauty. Its internal structure consists of three layers of planing laid horizontally and vertically. This design gives the board good strength and stability, which can meet the needs of different decoration and furniture manufacturing. It is a material widely used in modern decoration and furniture manufacturing.

Decorative particle board Parameters

| Item | Parameter |

| Place of Origin | China |

| MOQ | 1000 pc |

| General Specifications | 8mm, 18mm |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Regenerated Wooden Base |

| Transportation | By Sea/By land |

| Quality/Safety Certification | GB/T19001-2016/ISO9001:2015, Hi-tech Enterprise, Attestation of Chinese Environment Mark |

| Factory Nature | China Manufacturers Suppliers Factory |

Decorative particle board Features

Premium Board Grades

Decorative Particle Board is available in a variety of grades, including OSB-1, OSB-2, OSB-3 and OSB-4, with OSB-4 offering the highest resistance to moisture and structural deformation. The moisture resistance coefficient of OSB-4 boards is above 0.95, a significant improvement over OSB-1's 0.65. This allows OSB-4 to absorb water and expand only 3% - 5% when used in a humid environment, much lower than OSB-1's 8% - 12%, effectively preventing the board from deforming or being damaged by water absorption, and extending the board's service life.

Three-layer staggered structure

The board is designed with a three-layer structure, with each layer of shavings laid horizontally and vertically. This structure not only improves the overall strength of the board, but also enhances its stability and resistance to deformation. Experimental data shows that the static bending strength of the three-layer staggered Decorative Particle Board can reach 35 - 45 MPa, which is 40% - 60% higher than that of ordinary single-layer structural boards. This structural design enables the board to evenly disperse stress when bearing weight and external force, reducing the risk of cracking and deformation, and ensuring long-term reliability.

Moderate density

The density of Decorative Particle Board is usually 600-750 kg/m³, which makes it have good strength and relatively light weight. In practical applications, boards with a density of 600-750 kg/m³ can not only ensure sufficient load-bearing capacity, but also be easy to process and carry. For example, when making furniture, the weight of a board with a density of 650 kg/m³ is only 60%-70% of that of a solid wood board, which greatly reduces the difficulty and transportation cost of furniture while maintaining good durability.

Rich thickness specifications

The board is available in a variety of thickness specifications, including 6mm, 9mm, 11mm, 15mm, 18mm, 25mm, etc. Boards of different thicknesses are suitable for different application scenarios. For example, 6mm thick boards are often used to make lightweight partitions and decorative panels; 18mm thick boards are suitable for furniture frames and floor bases with high load-bearing requirements. Experiments show that when the 18mm thick Decorative Particle Board is subjected to a uniformly distributed load of 1000N, its deflection is only 2.3mm, which is much lower than the 5mm specified in the building decoration standard, ensuring the stability and safety of the structure.

Standard size specifications

The common size specifications of Decorative Particle Board are 1220×2440mm (4×8ft) or 1250×2500mm (European standard). This standardized size design is convenient for transportation, storage and installation. In actual construction, standard size boards can reduce the workload of cutting and splicing, and improve construction efficiency. At the same time, standardized sizes are also conducive to the coordination with various building components and furniture parts, ensuring the smooth progress of the decoration and furniture manufacturing process.

Excellent bending strength

The board has excellent bending strength and can withstand large bending stress without breaking. Experimental tests show that its bending strength can reach 40-50 MPa, which is 20%-30% higher than ordinary plywood. This means that in actual use, Decorative Particle Board can adapt to the settlement and deformation of buildings to a certain extent, reduce cracking and damage caused by external forces, and is particularly suitable for architectural decoration and furniture structures that require a certain degree of flexibility.

Good moisture resistance

Decorative Particle Board has good moisture resistance and can effectively resist moisture erosion. Its water absorption thickness expansion rate is only 8%-12%, which is much lower than the 20%-30% of solid wood boards. After 48 hours of water immersion test, the strength retention rate of the board can still reach more than 75%. This moisture resistance makes it suitable for places with high humidity such as kitchens and bathrooms, effectively preventing the board from deforming and moldy due to moisture, extending the service life of the board, and providing users with a comfortable indoor environment.

Environmental and safety certification

The board has passed a number of strict environmental and safety certifications, including GB/T19001-2016/ISO9001:2015 quality management system certification, high-tech enterprise certification and China Environmental Labeling certification. These certifications show that every link, from raw material procurement, production and processing to finished product inspection, strictly follows environmental and safety standards. The formaldehyde emission of the board is only 0.08 mg/m³, which is far lower than the 0.12 mg/m³ stipulated by the national E1 standard, ensuring the environmental performance of the product and providing users with convenient, healthy and safe material selection.

Decorative Particle Board Application

Furniture manufacturing

Decorative Particle Board is an ideal material for furniture manufacturing. Its three-layer staggered structure and moderate density give it good processing performance and mechanical strength. In actual production, it can be used to manufacture various types of furniture, such as wardrobes, cabinets, bookshelves, etc. For example, using 18mm thick Decorative Particle Board to make a wardrobe, its bending strength and static bending strength can ensure that the wardrobe remains stable in long-term use, and its load-bearing capacity meets daily needs. At the same time, its environmental performance meets the health standards of indoor furniture, providing users with a safe and comfortable living environment.

Indoor decoration

In the field of interior decoration, Decorative Particle Board is widely used in the decoration of walls, ceilings and floors. Its rich thickness specifications and standard sizes enable it to adapt to various decoration needs. For example, in wall decoration, using 9mm thick Decorative Particle Board as the base board can provide a flat base, which is convenient for subsequent paint or wallpaper construction. At the same time, its good moisture-proof performance makes it suitable for wall base treatment in humid areas such as kitchens and bathrooms, effectively preventing the wall from peeling and mold due to moisture, and extending the service life of the decoration.

Building Formwork

As a building formwork material, Decorative Particle Board has good strength and stability. Its bending strength and tensile strength can withstand the lateral pressure and vibration during the concrete pouring process. Experimental data show that its tensile strength can reach 15-20 MPa. Compared with traditional building formwork materials, it can reduce the thickness and weight of the formwork and improve construction efficiency. In actual construction projects, the formwork system used for high-rise buildings can be reused 10-15 times, which reduces construction costs. At the same time, its environmental protection performance also helps to reduce construction waste, which is in line with the development trend of green buildings.

Shipbuilding

In shipbuilding, Decorative Particle Board is widely used in the decoration and structural components of the cabin interior due to its good moisture-proof and anti-corrosion properties. The ship environment has high humidity and strong salt spray corrosion, and the moisture resistance coefficient of the board is as high as 0.95, which can effectively resist the erosion of moisture and salt spray. For example, in the wall and ceiling decoration of the cabin, the use of Decorative Particle Board can ensure long-term beauty and practicality and reduce maintenance costs. Its environmental performance also meets the health requirements of the ship's internal environment, providing a comfortable and safe living and working space for crew members and passengers.

Aerospace Interiors

The lightweight and high-strength characteristics of Decorative Particle Board make it potentially useful in the field of aerospace interiors. Its density is only 600-750 kg/m³, which greatly reduces the weight compared to traditional metal materials. At the same time, its static bending strength and flexural strength can meet the structural requirements of aviation interiors. Experiments have shown that in vibration and pressure tests that simulate flight environments, interior parts made of Decorative Particle Board can remain stable without deformation or damage. This helps increase the payload of aircraft, reduce fuel consumption, and provide passengers with a comfortable riding environment.

Packaging Materials

The sheet can be processed into various packaging materials, such as packaging boxes, packaging pallets, etc. Its good strength and stability can protect the items in the package from damage during transportation. For example, a packaging box made of 15mm thick Decorative Particle Board has a compressive strength of 300-400 kPa, which can withstand a certain stacking pressure and ensure the safe transportation of items. At the same time, its environmental performance meets the sustainable development requirements of packaging materials, reduces pollution to the environment, and is a green and efficient packaging solution.

Decorative Particle Board Maintenance

Daily cleaning and maintenance

In order to maintain the good appearance and performance of Decorative Particle Board, daily cleaning is essential. It is recommended to use a soft dry cloth or a slightly damp cloth to gently wipe the surface of the board to remove dust and stains. If there are stubborn stains on the surface of the board, you can use a small amount of neutral detergent, such as detergent dilution, to wipe it, then wipe off the detergent residue with a clean damp cloth, and wipe it dry with a dry cloth. Avoid using detergents containing alcohol, acidic or alkaline ingredients to avoid damaging the decorative layer and protective coating on the surface of the board. Regular cleaning can effectively prevent dirt from accumulating on the surface of the board for a long time and maintain the beauty and decorative effect of the board. For example, in furniture manufacturing, deep cleaning once a quarter can ensure the finish and color of the furniture surface and extend the service life of the furniture.

Moisture-proof and moisture-proof treatment

Although Decorative Particle Board has good moisture-proof performance, it is still necessary to pay attention to moisture-proof and moisture-proof during use. In a humid environment, the direct contact between the board and the water source should be minimized. For example, in places with high humidity such as kitchens and bathrooms, a layer of waterproof paint or waterproof veneer can be applied on the surface of the board to enhance its moisture resistance. At the same time, keeping the room well ventilated can help reduce air humidity and prevent the board from swelling, deformation and other problems due to moisture. In actual applications, after using Decorative Particle Board with moisture-proof treatment in an environment with a humidity of 80% for one year, its water absorption and expansion rate is only about 5%, which is much lower than the 15% - 20% of untreated boards, effectively ensuring the quality and performance of the board.

Avoid scratches with sharp objects

In daily use, the surface of Decorative Particle Board should be avoided from contact with sharp objects, such as nails, knives, high heels, etc. Sharp objects may scratch the decorative layer on the surface of the board, affecting its appearance. If you need to place heavy objects or use tools on the surface of the board, it is recommended to place cushions or protective films at the contact points to disperse the pressure and reduce damage to the surface of the board. For example, when placing a computer or file on the Decorative Particle Board surface of an office desk, using a soft mouse pad and file pad can effectively prevent scratches on the desktop and keep the surface flat and smooth.

Check the connection parts regularly

For furniture and building structures made of Decorative Particle Board, the screws, nails and other fasteners at the connection parts should be checked regularly for looseness. If looseness is found, it should be tightened in time with appropriate tools, but be careful not to over-tighten to avoid damaging the board. At the same time, check whether the joints between the boards are tight, and if there are gaps, they should be repaired in time. Regular inspections can ensure the stability and safety of the structure and avoid the displacement or damage of the board due to loose connection parts. For example, during the use of wooden wardrobes, checking the connection parts every six months can timely discover and solve potential problems and extend the service life of the wardrobe.

Avoid long-term direct sunlight

Long-term direct sunlight may cause the decorative layer on the surface of Decorative Particle Board to fade, crack or age. Therefore, during use, the board surface should be avoided from long-term direct sunlight. If direct sunlight cannot be avoided, shade facilities such as curtains and awnings can be installed to reduce the impact of ultraviolet rays on the board. For example, when using outdoor furniture made of Decorative Particle Board, equipping it with a parasol or placing it in a shaded area can effectively protect the surface decorative layer of the board and maintain its long-term stability of color and texture.

Professional maintenance and repair

If Decorative Particle Board is severely damaged or requires professional maintenance, you should promptly seek help from professionals or institutions with relevant experience. Professional maintenance personnel can use special tools and materials to repair, replace or redecorate the board. During the repair process, they can develop a suitable repair plan based on the degree of damage to the board and customer needs to ensure that the repaired board can achieve the expected effect in appearance and performance. For example, in building decoration projects, in the case of damage to the board due to impact, professional maintenance personnel can use partial replacement or surface repair technology to restore the decoration to its original state and reduce the impact of maintenance on the building's use function.

Decorative Particle Board FAQs

Q1: What is the main material of Decorative Particle Board?

A1: Decorative Particle Board is usually pressed from wood particles, and the surface is covered with decorative laminate or thin wood veneer.

Q2: What are the thickness specifications of this board?

A2: Decorative Particle Board offers a variety of thickness specifications, 8mm and 8mm.

Q3: Is this board suitable for outdoor use?

A3: Although decorative particle board has good stability, its waterproof performance is relatively weak and it is not recommended to be used directly in outdoor environments. If outdoor use is required, additional waterproofing is recommended.

Q4: Is the board easy to clean?

A4: The cleaning process is very convenient. Use a soft dry or slightly damp cloth to gently wipe the surface to remove dust and stains. For stubborn stains, a mild detergent can be used.

Q5: Does this board provide customized services?

A5: Yes, some suppliers provide customized services, and can customize the size and thickness according to customer needs.

Q6: How long is the service life of this board?

A6: Under normal indoor conditions, the service life of Decorative Particle Board can reach more than 10 years. Its durability and stability depend on the quality of materials, manufacturing process and daily cleaning and maintenance.

Q7: What is the fire rating of this board?

A7: Some models of Decorative Particle Board have a B1 fire rating, which can effectively prevent the spread of fire.