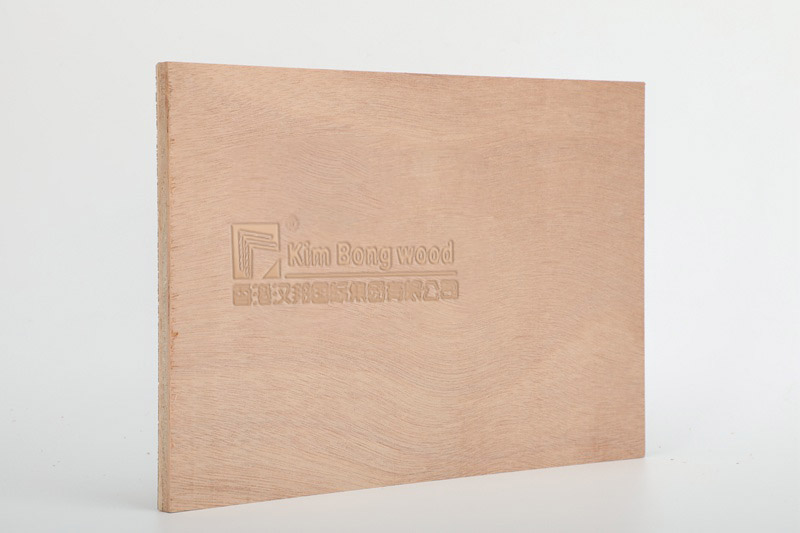

Multi Layer Board Wood

Please click the button below to contact us.

Introduction:Multi Layer Board Wood is a board made of multiple layers of thin wood boards that are staggered and glued together. It is commonly used in many fields such as construction, furniture manufacturing and decoration. Its multi-layer structure provides good stability and strength while reducing the natural deformation of wood.

Product Description

Multi Layer Board Wood is a board made of multiple layers of thin wood boards that are staggered and glued together. It is commonly used in many fields such as construction, furniture manufacturing and decoration. Its multi-layer structure provides good stability and strength while reducing the natural deformation of wood.

Multi Layer Board Wood Parameters:

| Item | Parameter |

| Place of Origin | China |

| MOQ | 1000 pc |

| General Specifications | 5mm, 9mm, 12mm, 15mm, 18mm |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Regenerated Wooden Base |

| Transportation | By Sea/By land |

| Quality/Safety Certification | GB/T19001-2016/ISO9001:2015, Hi-tech Enterprise, Attestation of Chinese Environment Mark |

Multi Layer Board Wood Product Features

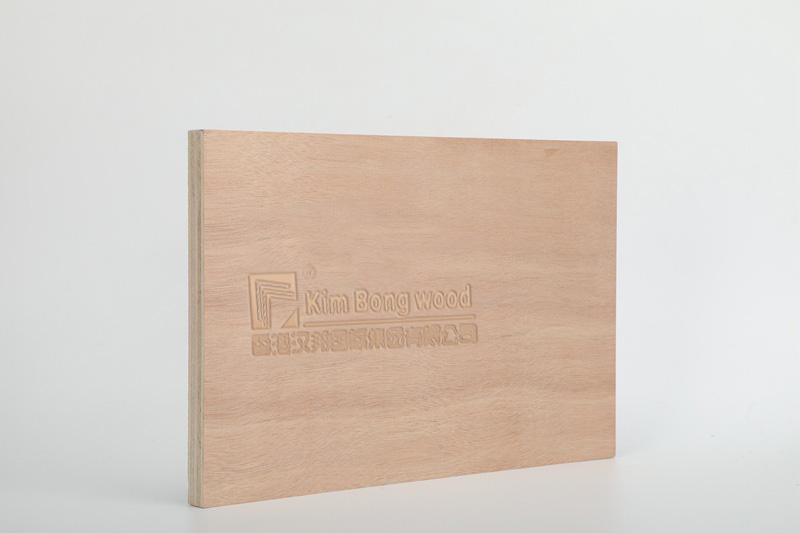

Multi-layer staggered structure

The core feature of Multi Layer Board Wood lies in its multi-layer staggered structure. This structure effectively reduces the natural deformation of wood, such as warping and cracking, by staggering and gluing thin wood boards at 90 degrees. For example, standard multi-layer board wood usually contains 3 to 7 layers of thin wood boards, each layer is about 1.5 mm thick, and this structural design significantly improves the overall stability of the board.

High Strength and Stability

The high strength and stability of multi-layer board wood make it an ideal choice for construction and furniture manufacturing. Its compressive strength and bending strength are higher than those of ordinary solid wood boards, and it can withstand greater loads. For example, the compressive strength of 18 mm thick multi-layer board wood can reach 10 MPa and the bending strength can reach 50 MPa, which is suitable for applications with high load-bearing requirements.

Good processing performance

Multi-layer board wood has good processing performance and is easy to cut, drill and carve. Its smooth surface is suitable for various surface treatments, such as painting, veneer, etc. For example, 9 mm thick multi-layer board wood is suitable for furniture manufacturing and can be easily processed into various shapes and sizes to meet different design requirements.

Environmental characteristics

Multi-layer board wood is usually bonded with environmentally friendly glue, which meets international environmental standards. Its production process generates less waste and has less impact on the environment. For example, some high-end multi-layer board wood uses E0 grade environmentally friendly glue, which has extremely low formaldehyde emission and is suitable for indoor use.

Multiple specifications to choose from

Multi Layer Board Wood offers a variety of standard specifications, including 5 mm, 9 mm, 12 mm, 15 mm and 18 mm thick boards. These specifications can meet the needs of different application scenarios. For example, 5 mm thick multi-layer board wood is suitable for lightweight furniture and decorative purposes, while 18 mm thick boards are suitable for buildings and furniture structures with higher load-bearing requirements.

Multi Layer Board Wood Application scenarios

Furniture manufacturing

In the field of furniture manufacturing, Multi Layer Board Wood is an ideal material. Its good processing performance and high strength enable it to manufacture various types of furniture, such as cabinets, bookcases, tables and chairs. For example, 9 mm thick plywood is suitable for making lightweight furniture, such as bookshelves and TV cabinets, and can provide sufficient strength and stability while maintaining the lightness of the furniture.

Building decoration

In building decoration, plywood is widely used for laying floors, walls and ceilings. Its multi-layer structure provides good stability and deformation resistance, which can effectively reduce deformation and cracking after construction. For example, 12 mm thick plywood is suitable for floor laying, which can withstand the load of daily walking while providing good flatness and stability.

Interior decoration

In interior decoration, plywood can be used to make decorative panels, partitions and decorative lines. Its smooth surface is easy to carry out various surface treatments, which can meet different decorative needs. For example, 15 mm thick plywood is suitable for making interior partitions, which can provide sufficient strength and stability while maintaining the beauty of the decoration.

Packaging materials

In the field of packaging, plywood can be used to make packaging boxes and pallets. Its high strength and stability can effectively protect the items in the package and reduce damage during transportation. For example, 18mm thick multi-layer board wood is suitable for making packaging boxes for heavy items, which can withstand large loads and ensure the safety of packaging.

Multi Layer Board Wood Cleaning and maintenance

Daily cleaning

For daily cleaning, use a soft dry or slightly damp cloth to gently wipe the surface to remove dust and stains. For stubborn stains, you can use a mild detergent, but avoid using detergents containing alcohol or acetone to avoid damaging the surface.

Regular inspection

Regularly check the surface and joints of the board to ensure that they are intact. If scratches or coating peeling are found on the surface, they should be repaired in time to maintain their beauty and functionality.

Protective measures

During cleaning and maintenance, avoid scratching the surface with hard objects to avoid damaging the board. At the same time, avoid long-term exposure to humid environments to prevent the board from being deformed by moisture.

Multi Layer Board Wood FAQs

Q1: What is the main material of Multi Layer Board Wood?

A1: Multi Layer Board Wood is usually made of multiple layers of thin wood boards staggered and glued together, and the thickness of each layer of thin wood boards is about 1.5 mm.

Q2: What are the thickness specifications of this board?

A2: Multi Layer Board Wood is available in a variety of thicknesses, including 5mm, 9mm, 12mm, 15mm and 18mm.

Q3: Is this board suitable for outdoor use?

A3: Although multi-layer board wood has good stability, its waterproof performance is relatively weak and it is not recommended to be used directly in outdoor environments. If outdoor use is required, additional waterproofing is recommended.

Q5: Does this board provide customized services?

A5: Yes, customized services are provided, and the size and thickness can be customized according to customer needs.

Q6: What is the fire rating of this board?

A6: Some models of Multi Layer Board Wood have a B1 fire rating, which can effectively prevent the spread of fire.

Q7: Will this board affect indoor air quality?

A7: No. Although glue is used in the production process of multi-layer board wood, its formaldehyde emission is extremely low and meets international environmental standards. Some high-end products use E0-level environmentally friendly glue, and the formaldehyde emission is almost negligible, which is suitable for indoor use.